What is gland packing? Gland packing, also known as stuffing box packing, is a type of mechanical seal used to prevent the leakage of fluids or gases between two surfaces that move relative to each other.

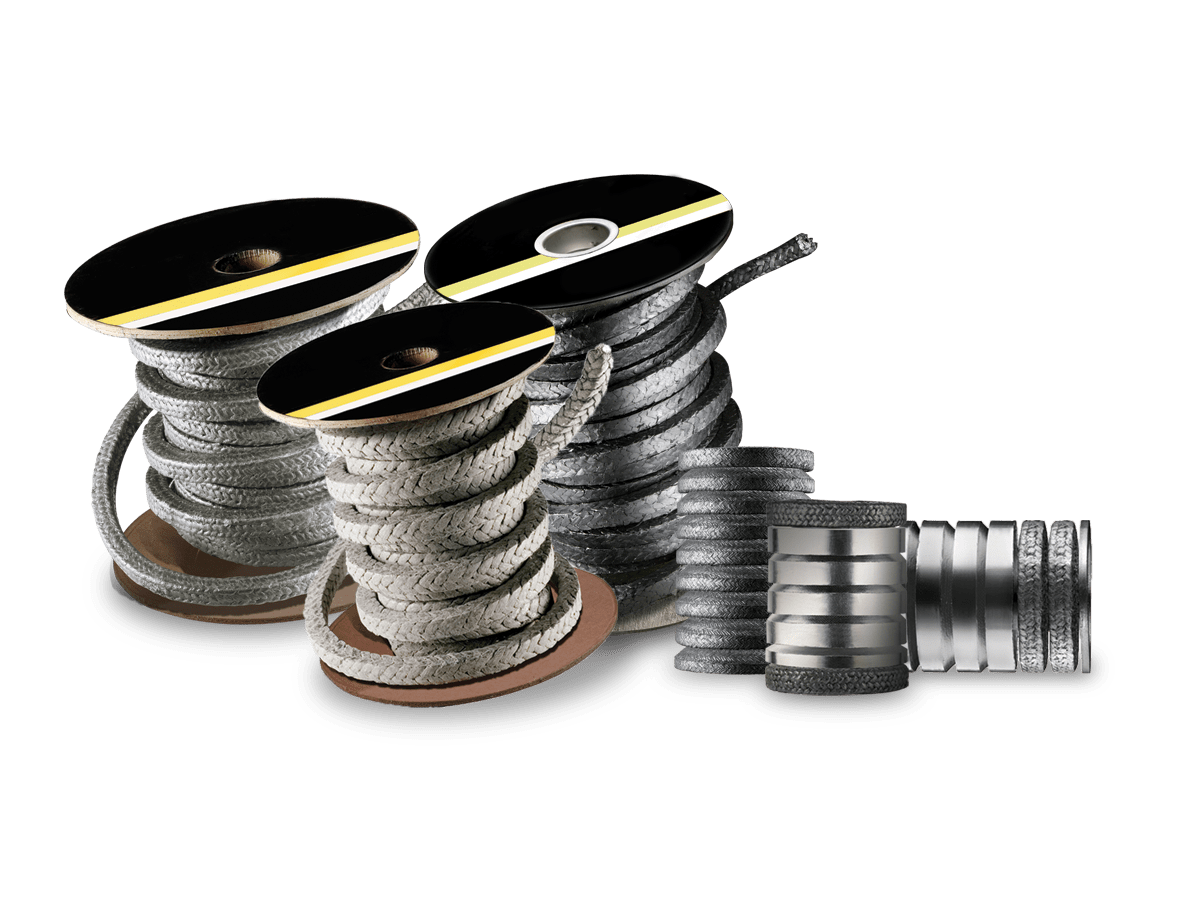

Gland packing is typically made of a soft, pliable material, such as rubber, graphite, or PTFE, and is installed in a stuffing box, which is a chamber that surrounds the moving shaft or rod. The packing is compressed around the shaft or rod, creating a seal that prevents leakage.

Gland packing is used in a wide variety of applications, including pumps, valves, compressors, and engines. It is a relatively simple and inexpensive sealing method, and it can be used in a wide range of operating conditions.

However, gland packing can also be a source of leakage, especially if it is not properly installed or maintained. Regular inspection and maintenance of gland packing is essential to ensure that it is functioning properly and preventing leakage.

What is Gland Packing

Gland packing, also known as stuffing box packing, is a type of mechanical seal used to prevent the leakage of fluids or gases between two surfaces that move relative to each other. It is typically made of a soft, pliable material, such as rubber, graphite, or PTFE, and is installed in a stuffing box, which is a chamber that surrounds the moving shaft or rod. The packing is compressed around the shaft or rod, creating a seal that prevents leakage.

- Material: Gland packing can be made from a variety of materials, including rubber, graphite, PTFE, and other soft, pliable materials.

- Function: Gland packing prevents the leakage of fluids or gases between two surfaces that move relative to each other.

- Installation: Gland packing is installed in a stuffing box, which is a chamber that surrounds the moving shaft or rod.

- Compression: The packing is compressed around the shaft or rod, creating a seal that prevents leakage.

- Applications: Gland packing is used in a wide variety of applications, including pumps, valves, compressors, and engines.

- Maintenance: Regular inspection and maintenance of gland packing is essential to ensure that it is functioning properly and preventing leakage.

Gland packing is a relatively simple and inexpensive sealing method, and it can be used in a wide range of operating conditions. However, it can also be a source of leakage, especially if it is not properly installed or maintained. Regular inspection and maintenance of gland packing is essential to ensure that it is functioning properly and preventing leakage.

Material

The material of gland packing is important because it determines the seal's performance characteristics, such as its temperature and pressure resistance, chemical compatibility, and wear resistance. For example, rubber gland packing is suitable for low-pressure applications, while graphite gland packing is suitable for high-temperature applications. PTFE gland packing is chemically inert and suitable for use with a wide range of fluids.

The choice of gland packing material will depend on the specific application requirements. It is important to select a material that is compatible with the fluid being sealed and the operating conditions. Improperly selected gland packing material can lead to leakage or premature failure.

In addition to the material, the design of the gland packing is also important. The packing must be properly compressed to create a seal, but it must not be over-compressed, as this can lead to excessive friction and wear. The gland packing must also be able to accommodate movement of the shaft or rod without leaking.

Function

This is the primary function of gland packing, and it is what makes it such a useful sealing method. Gland packing is able to prevent leakage even when the two surfaces are moving relative to each other, which is a common occurrence in many industrial applications.

For example, gland packing is used in pumps to prevent the leakage of fluid between the pump shaft and the pump housing. It is also used in valves to prevent the leakage of fluid between the valve stem and the valve body. In both of these applications, the gland packing is able to prevent leakage even though the shaft or stem is moving relative to the housing or body.

The ability of gland packing to prevent leakage is essential for the proper functioning of many industrial machines and systems. Without gland packing, these machines and systems would not be able to operate efficiently or safely.

Installation

The installation of gland packing in a stuffing box is a critical part of the sealing process. The stuffing box is a chamber that surrounds the moving shaft or rod, and it is designed to hold the gland packing in place and to provide a seal between the shaft or rod and the stuffing box wall.

The gland packing is installed in the stuffing box by first packing the stuffing box with aof packing material. The packing material is then compressed using a gland follower, which is a device that is used to apply pressure to the packing material. The gland follower is tightened until the packing material is compressed to the desired level.

The correct installation of gland packing is essential for the proper functioning of the seal. If the packing is not properly installed, it can leak, which can lead to a loss of fluid or gas. In addition, if the packing is over-tightened, it can cause excessive friction and wear on the shaft or rod.

The installation of gland packing is a relatively simple process, but it is important to follow the manufacturer's instructions carefully. By following the manufacturer's instructions, you can ensure that the gland packing is properly installed and that the seal is functioning properly.

Compression

Compression is a critical aspect of gland packing, as it is what creates the seal that prevents leakage. The packing is compressed around the shaft or rod using a gland follower, which is a device that applies pressure to the packing. The amount of compression is important, as too little compression will not create a seal, and too much compression can damage the packing or the shaft or rod.

- Proper Compression: Proper compression of the packing is essential for a good seal. If the packing is not compressed enough, it will not be able to prevent leakage. However, if the packing is compressed too much, it can cause excessive friction and wear on the shaft or rod.

- Gland Follower: The gland follower is a device that is used to compress the packing. Gland followers can be made from a variety of materials, including metal, plastic, and composite materials. The type of gland follower used will depend on the specific application.

- Compression Ratio: The compression ratio is the ratio of the compressed packing to the uncompressed packing. The compression ratio is an important factor to consider when selecting gland packing. A higher compression ratio will result in a better seal, but it will also increase the friction and wear on the shaft or rod.

Compression is a key factor in the performance of gland packing. By understanding the importance of compression and how to properly compress the packing, you can ensure that your gland packing will provide a good seal and last for a long time.

Applications

Gland packing is a versatile sealing solution that finds applications in a wide range of industries and applications. Its ability to prevent leakage in dynamic sealing environments makes it a critical component in many essential systems and machinery.

In pumps, gland packing is used to seal the rotating shaft, preventing leakage of the fluid being pumped. This is essential for maintaining the pump's efficiency and preventing contamination of the fluid. Gland packing is also used in valves to seal the stem, preventing leakage of the fluid flowing through the valve. This is critical for ensuring the valve's proper operation and preventing unintended fluid loss.

Compressors rely on gland packing to seal the piston or rotating shaft, preventing leakage of the compressed gas. This is essential for maintaining the compressor's efficiency and preventing contamination of the gas. Gland packing is also used in engines to seal the crankshaft, preventing leakage of oil and combustion gases. This is critical for maintaining the engine's performance and preventing catastrophic failure.

The use of gland packing in these diverse applications highlights its importance as a component of "what gland packing is." It demonstrates the versatility and effectiveness of gland packing in preventing leakage and ensuring the proper operation of essential systems and machinery.

Maintenance

Regular inspection and maintenance of gland packing is crucial for ensuring its proper functioning and preventing leakage. Gland packing, as discussed earlier, is a mechanical seal used to prevent the leakage of fluids or gases between two surfaces that move relative to each other. Its effectiveness relies heavily on proper maintenance.

Inadequate maintenance can lead to several issues. Over time, gland packing can become worn or damaged, reducing its sealing ability and increasing the risk of leakage. Additionally, improper adjustment of the gland follower can result in either insufficient compression, leading to leakage, or excessive compression, causing increased friction and wear on the shaft or rod.

Regular inspection allows for early detection of any issues with the gland packing. This includes checking for signs of wear, damage, or leaks. Maintenance involves adjusting the gland follower to maintain the optimal compression of the packing, ensuring a proper seal without excessive friction. Proper lubrication is also essential to minimize wear and extend the lifespan of the gland packing.

By understanding the importance of maintenance as an integral part of "what gland packing is," industries can ensure the longevity and effectiveness of their sealing systems. Regular inspection and maintenance contribute to preventing costly repairs, unplanned downtime, and potential hazards associated with leakage.

FAQs on Gland Packing

This section addresses frequently asked questions and misconceptions surrounding gland packing, providing concise and informative answers to enhance understanding of its purpose and usage.

Question 1: What is the primary function of gland packing?

Answer: Gland packing serves as a mechanical seal, preventing leakage of fluids or gases between two surfaces that move relative to each other, ensuring system integrity.

Question 2: In which industries is gland packing commonly used?

Answer: Gland packing finds applications in diverse industries, including manufacturing, power generation, oil and gas, and water treatment, among others.

Question 3: What materials are typically used in gland packing?

Answer: Gland packing is often made from flexible materials like rubber, graphite, or PTFE, each offering unique properties for specific applications.

Question 4: How crucial is regular maintenance for gland packing?

Answer: Regular inspection and maintenance are essential. They help detect wear or damage, adjust compression, and ensure optimal performance and longevity.

Question 5: What are some common causes of gland packing failure?

Answer: Gland packing failure can result from improper installation, inadequate maintenance, excessive wear, or chemical incompatibility with the sealed fluid.

Question 6: How can I select the most suitable gland packing material for my application?

Answer: Material selection should consider factors such as fluid compatibility, temperature and pressure ranges, and specific industry requirements.

In summary, gland packing plays a vital role in sealing systems, preventing leakage and ensuring efficient operation. Proper selection, installation, and maintenance are crucial for its effectiveness.

Transition to the next article section:

Conclusion

Gland packing, a fundamental component in mechanical systems, plays a pivotal role in preventing leakage and ensuring system integrity. Its effectiveness relies on proper selection, installation, and maintenance. As discussed in this article, gland packing finds applications in diverse industries, from manufacturing to power generation and beyond.

The key takeaway is that gland packing serves as a crucial mechanical seal, preventing the leakage of fluids or gases between moving surfaces. Its versatility stems from the availability of various materials like rubber, graphite, and PTFE, each tailored for specific applications. Regular inspection and maintenance are essential to ensure optimal performance and longevity.

Understanding the significance of gland packing empowers industries to make informed decisions regarding sealing solutions. By selecting the appropriate gland packing material, installing it correctly, and implementing a proactive maintenance plan, industries can enhance the efficiency and reliability of their systems while minimizing the risk of leakage and downtime.

Calculate The Construction Costs Of A 12 X 12 Room: A Comprehensive Guide

Resolving "No More Spool Space" Errors In Teradata Systems

Top Hacks To Prevent Cockroaches From Invading Your Italian Bathroom

NonAsbestos Gland Packing Flax Fiber Gland Packing Manufacturer from

Gland Packing

Gland Packing From A UK Leading Suppler Barnwell